Hydraulic scissor lift tables

E-mail: sale@gidrolast.com

International sales team

Technical specifications

| Capacityto 15.000kg (33.000lb); |

| Dimensions of tablefrom 500 х 800mm (20"x 30") to 12.000 х 4.000mm (470"x160"); |

| Max.lifting heightto 12.000mm (450"); |

| Min.height of the platformfrom 100 mm (4"); |

| Operating temperaturefrom -20° С to +50° С, (-4°F...to 122°F); |

| Explosion protection ATEX ratedare available; |

Description

Gidrolast the most diverse, highest quality, and longest lasting scissor lift tables in the world providing the most stable, dependable, and versatile method of lifting heavy loads, industrial scissor lift tables are our most popular and efficient style of industrial lift. Because of their simplicity and few moving parts, maintenance-free bushings, and wide acceptance by customers, scissors lift tables provide many years of trouble free operation for relatively small capital investment.

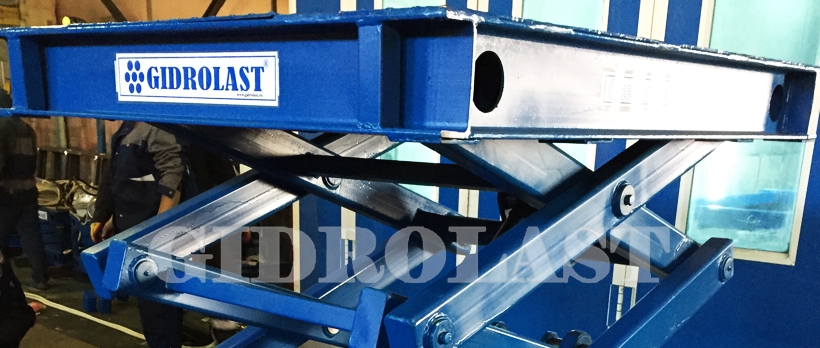

Scissor lift mechanisms are manufactured in a vast array of configurations, are easily modified by narrowing, widening, combining or stacking, and can efficiently move loads of any size and capacity to heights of more than 10m. Completely pneumatic or mechanical scissors tables are also available.

Every lift table is designed and manufactured to meet the industry safety requirements set forth in ANSI MH29.1, and can be modified or customized to customer specifications.

All Gidrolast lifts are designed to exceed the requirements of ANSI MH29.1, Safety Requirements for industrial scissor lifts.

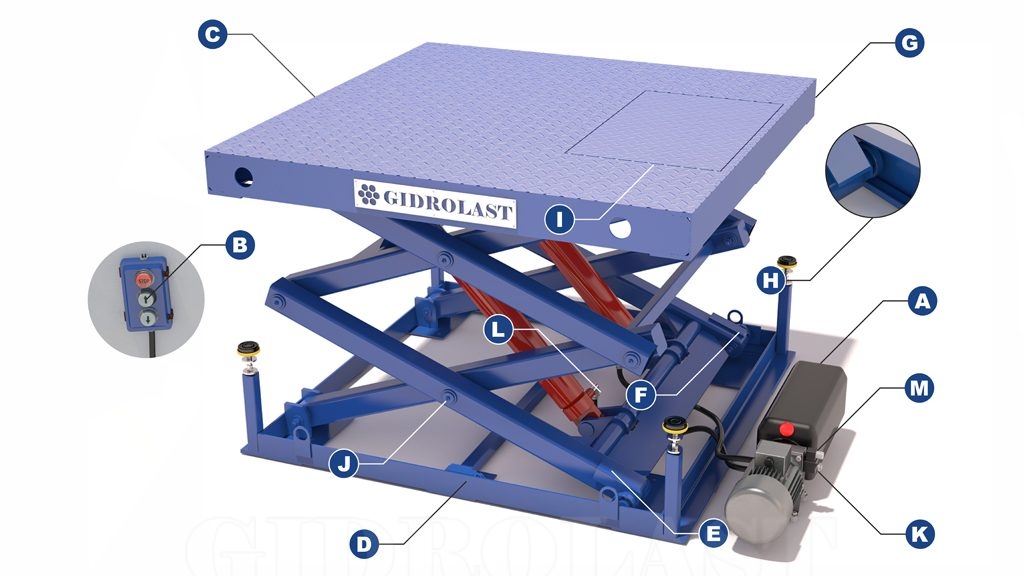

Product details

- A. Remote hydroelectric station, 1,5 kW, length of high-pressure hose is 1500 mm.

- B. Remote control panel – 1 pc.

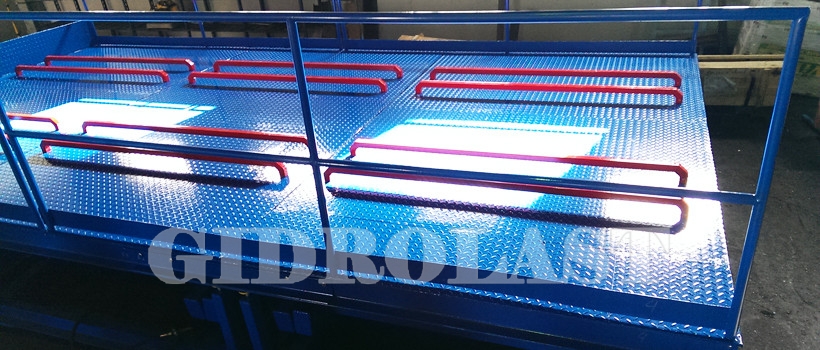

- C. Lenticular corrugated coating.

- D. Limit switches for limiting the lifting height and shutting down the hydraulic station after lowering.

- E. Mechanical movement stops in the folded state.

- F. Mechanical movement limiters in the unfolded state.

- G. Reinforced lifting platform.

- H. Protection against tilting of the scissor lift.

- I. Inspection service hatch.

- J. Press – oilers (greases) for service maintenance of all mobile units of the lifting mechanism.

- K. Chokes for adjusting the lifting and lowering speed of the lifting table.

- L. Safety valves (preventing the table from falling in case of pressure loss in the hydraulic system).

- M. Overload protection.

Lifting platforms are designed to carry dynamic and off centre loads within the BS EN 1570 description of half of the load on half of the platform length, 1/3 of the load on half of the platform width. Platforms made with square not radius edges for greater strength, better load support and machinery mounting. Platforms can be smooth or slip resisting tear pattern plate.

Heavy duty, quality arm roller bearings. Crown head, yoke type, track roller bearings with a twin ball and cage, lithium greased and sealed for life. Chromed for heavy duty or stainless steel axle and cylinder pins as options.

Integral (within baseframe) or remote power packs. IP54 as standard. 3 phase, single phase or low voltage DC and manual pumps available. Hold to run emergency lowering.

The construction, hydraulic and electrical systems conform to the requirements of European standards. Typically these include safety gaps and clearances between fixed and moving parts, moving and moving parts, hose break rupture valves, mechanically actuated safety trip device, manually operated blocking devices, overload detection and protection. Most of Gidrolast scissor lift tables are supplied with an individual Load Test Certificate as well as the applicable Certificate of Conformity or Certificate of Incorporation.

Why choose our company?

Quote solutions

Do not hesitate to contact our International sales team, located at Milan, ITALY at your disposal for all commercial and technical requests or any other inquiry.

For your information, Gidrolast searchs for foreign distributors to make known our Company and sell our products.

If you want advanced technical information, send us the following form and we will get back to you as soon as possible.

just scan the barcode.

Quote solutions

Do not hesitate to contact our International sales team, located at Milan, ITALY at your disposal for all commercial and technical requests or any other inquiry.

For your information, Gidrolast searchs for foreign distributors to make known our Company and sell our products.

If you want advanced technical information, send us the following form and we will get back to you as soon as possible.

Online request

Photo presentation